- 快速铣削的高能量操作;用于样品抛光的低能量操作

- 两个独立的可调Truefocus离子源

- 离子源在宽范围的操作能量(100eV至10kev)上保持其小光束直径

- Adjustable 10-inch touch screen with a user-friendly interface for simple setup of milling parameters

- Create pristine cross-section samples with theCross-section station(optional)

- 可调节铣削角度范围为0至+ 10°

- In situ viewing and image capture during milling

- Automatic termination by time or temperature

- Liquid nitrogen-cooled sample stage (optional)

Advanced sample preparation

For many of today’s advanced materials, analysis by SEM is an ideal technique for rapidly studying material structure and properties. Fischione Instruments' Model 1061 SEM Mill is an excellent tool for creating the sample surface characteristics needed for SEM imaging and analysis.

For many of today’s advanced materials, analysis by SEM is an ideal technique for rapidly studying material structure and properties. Fischione Instruments' Model 1061 SEM Mill is an excellent tool for creating the sample surface characteristics needed for SEM imaging and analysis.

接受大型样本尺寸

The SEM Mill accepts the following sample sizes:

Cross section*

最大值:0.39 x 0.39 x 0.157英寸(10 x 10 x 4.0 mm)

最小值:0.12 x 0.12 x 0.028英寸(3 x 3 x 0.7 mm)

Planar

1.25英寸直径x 1英寸高度(32 x 25 mm)

Automatic sample thickness sensing maximizes throughput, while magnetic encoding provides absolute positioning accuracy.

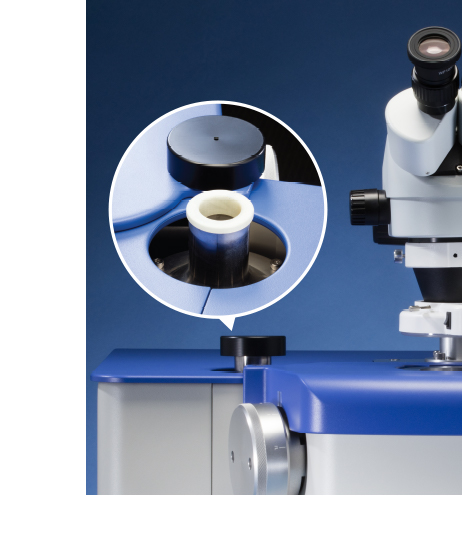

Cross-section station (optional)

The Fischione Instruments’ Cross-section station is a tool for creating pristine cross-section samples ready for ion milling in the SEM Mill. Click here to learn more about theCross-section station。

快速样品转移

The SEM Mill features a vacuum load lock for rapid sample exchange. The load lock is ergonomically designed; simply lift the load lock cover to load the sample holder onto the stage.

Replace the cover and evacuation of the load lock occurs within a few seconds. The vacuum secures the load lock cover in place during ion milling. An electronically controlled elevator then moves the sample into the milling position.

在铣削过程结束时,样品架返回装载锁,但保留真空直至用户排出。通风只需要几秒钟。

Vacuum or inert gas transfer capsule (optional)

可选的真空胶囊允许您在真空或惰性气体下将样品转移到SEM。

chamber

The SEM Mill’s vacuum chamber remains under continuous vacuum during operation. A load lock isolates the high chamber vacuum from ambient during sample exchange, ensuring optimal vacuum conditions.

Precise angle adjustment

离子源倾斜以提供所需的铣削角度。连续可调节的离子源倾斜角度范围为0至+ 10°。使用左和右离子源控制调节离子源角。

您可以选择使用一个或两个Truefocus离子源。如果您使用的两个离子源,可以独立调整光束角度。

当两个离子束被引导到样品表面之一时,铣削速率加倍;这种能力对于诸如样品的平面抛光等应用是有用的。188金宝搏亚洲体育与真人20

自动铣削角度调整(可选)

使用触摸屏自动铣削角度调节是SEM磨机的可用选择。添加此功能使您可以创建多步铣削序列,包括在整个铣削过程中自动调节铣削角度。

可编程样品运动

样品旋转360°旋转spe与变量ed and a sample rocking feature. The instrument automatically senses the sample thickness and establishes the milling plane, which maximizes throughput. A magnetic encoder provides absolute positioning accuracy.

综合舞台冷却(可选)

Although milling at low angles with low ion beam energies reduces sample heating, temperature-sensitive samples may require further cooling. Liquid nitrogen cooling of the sample stage is very effective in eliminating heat-induced artifacts.

Although milling at low angles with low ion beam energies reduces sample heating, temperature-sensitive samples may require further cooling. Liquid nitrogen cooling of the sample stage is very effective in eliminating heat-induced artifacts.

The SEM Mill’s liquid nitrogen system features a dewar located within the enclosure that is fully integrated and interlocked. The dewar is positioned near the operator for easy access. Two dewar options are available: a standard dewar for applications that require 3 to 5 hours of cooling during ion milling, or an extended dewar for applications that require 18+ hours of operation under cryogenic conditions. Temperature is continuously displayed on the touch screen.

可编程温度

The SEM Mill offers the ability to program and maintain a specific temperature between ambient and cryogenic.

在低温温度结束时,在通风之前,阶段温度自动增加到环境温度,以避免样品霜冻和污染。

A thermal safeguard can be programmed to a specific stage temperature threshold at which the ion sources will be deactivated if the liquid nitrogen in the dewar becomes depleted.

Automatic termination

离子铣削过程可以通过经过时间或通过温度自动终止。

Time

A timer allows milling to continue for a predetermined time and then turns off the energy to the ion sources when the time has elapsed. The sample remains under vacuum until the load lock is vented.

Temperature

The thermal safeguard associated with the sample cooling system will stop the process if the sample stage reaches a preset temperature.

In situ sample viewing

The ion milling process can be monitored in situ in the milling position when using either the optional stereo or the high-magnification microscope.

The viewing window is protected by a shutter, which prevents buildup of sputtered material that could interfere with sample observation.

立体显微镜(可选)

立体显微镜(7至45 x)增强样品观察。显微镜的长工作距离允许在铣削时以原位观察样品。

High magnification microscope (optional)

SEM磨机可以配置有525倍或1,960x的高倍率显微镜,耦合到CMOS相机和视频监视器,以在研磨期间查看样本并在原位捕获图像。该系统非常适合准备特定的网站样本。

样本照明

Both the high-magnification and stereo microscopes have light sources that provide top-down, user adjustable, reflected sample illumination.

触摸屏控制

通过10英寸触摸屏进入铣削参数,可以物理定位到您的优选高度和视角。从触摸屏中,您可以控制各种仪器参数,例如离子束能量,铣削角度,样品运动,样品位置和工艺终端。

通过10英寸触摸屏进入铣削参数,可以物理定位到您的优选高度和视角。从触摸屏中,您可以控制各种仪器参数,例如离子束能量,铣削角度,样品运动,样品位置和工艺终端。

For automated, unattended operation, you can program a series of milling sequences. A typical approach is to begin with rapid milling to remove larger amounts of sample material; then, as the sample thins, a lower milling rate to polish the sample. These milling sequences can be easily stored and recalled for future use.

During milling operations, milling sequence progress and instrument status are displayed in real time on the touch screen.

高级功能包括用于管理示例数据,维护和日志文件和图像存储的工具。

Access to instrument configuration, administrative and diagnostic tools, and maintenance and log files, is controlled through privileges granted to the various user levels and require login credentials.

Stack light system status indicator (optional)

An optional stack light allows you to view the system status from across the room.

自动燃气控制

两个质量流量控制器为离子源的处理气体提供独立和自动调节。气体控制算法在各种离子源研磨参数上产生稳定的离子束。工艺气体是超高纯度(99.999%)氩气。

完全集成的干式真空系统

集成的真空系统包括由多级隔膜泵背衬的涡轮分子阻力泵。这种无油系统可确保样品处理的清洁环境。

因为气体要求TrueFocus ion sourceare small, the 70 lps turbomolecular drag pump produces an operating system vacuum of approximately 5 x 10-4 mbar. The vacuum level is measured with a cold cathode, full-range gauge and is continuously displayed on the touch screen.

最小维护

Due to the efficiency of ionization, maintenance of theTrueFocus ion sourceis minimal and the components have an extremely long life. Material sputtered from the ion source is negligible, minimizing both sample contamination and component maintenance. Automated shuttering prevents the buildup of sputtered material on the viewing window. All system components are easily accessible for routine cleaning.

Remote diagnostics

188bet体育国际马克西Fischione仪器致力于支持mum instrument uptime. To that end, the SEM Mill has remote diagnostics capabilities built in. When connected to the Internet, the SEM Mill can be accessed remotely by Fischione Global Service for rapid troubleshooting and diagnostics support.

Service and preventive maintenance

To learn more about Fischione Global Service’s comprehensive service and preventive maintenance programs, contact188bet体育国际Fischione全球服务。